The spindle of the engraving machine is overheated after high-speed rotation, which will affect the service life of the spindle motor. How to solve this heat dissipation problem? It is necessary to use a water chiller. The water chillers are divided into air cooled type and water cooled type. The following is a detailed analysis of the differences between the two types of water chillers.

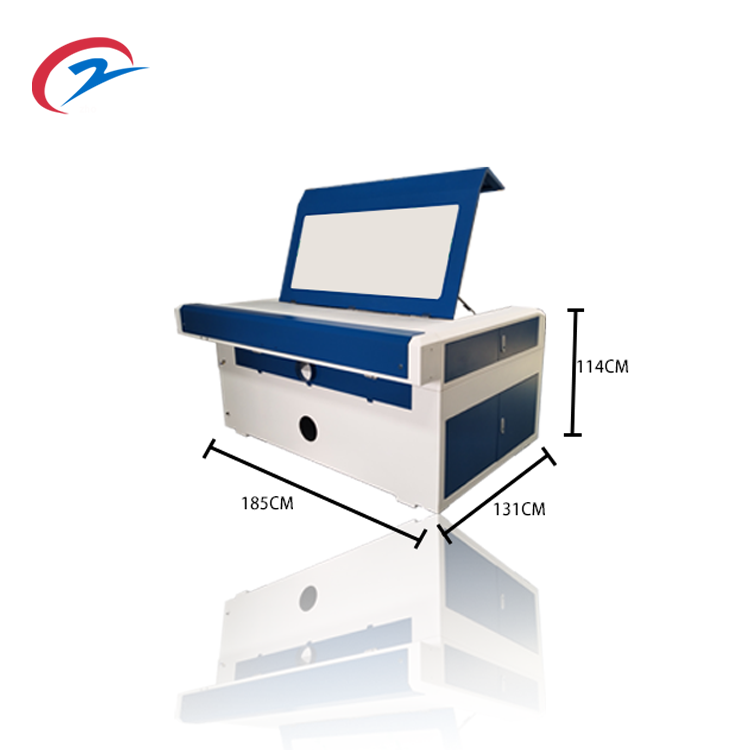

Co2 laser engraving and cutting machine,40W Co2 Laser Engraving Cutting Machine,Cnc Laser Engraving Machine.

For air cooling, the fan is used as the heat dissipation of the main shaft, which has no refrigeration function and is mainly cooled by forced air flow of the fan.

Water cooling adopts the method of water circulation to take away heat for the main shaft. High temperature water passes through the compressor of the chiller, the side pipe of the condenser, etc., and then returns to the main shaft after cooling the water temperature.

Which is better, air cooling or water cooling?

1. About noise.

Large air cooling noise, small water cooling noise.

2. Water temperature regulation.

Air cooling can not adjust the temperature, but can provide heat dissipation. In addition to cooling, water cooling can also set the required water cooling temperature to control the water temperature within a certain range. The flexibility of water temperature setting can meet the cooling requirements of different spindles.

3. Service life.

The service life of the chiller is longer than that of the air cooler, but it is also necessary to pay attention to the daily maintenance of the chiller, clean up the dust accumulated in the condenser and dust screen, and replace the circulating cooling water regularly.

According to different working principles, the following two types of chillers can be equipped with different spindle engraving machines.

1. The cooling chiller, represented by CW-3000 model, uses water circulation as the main shaft to dissipate heat. It is not equipped with a compressor, has no refrigeration function, and cannot control the water temperature. It is suitable for spindle engraving machines with low heat output.

2. The cooling chiller marked with CW-5000 model can be cooled by the compressor. The water temperature can be set on the temperature controller panel, which is more suitable for the heat dissipation of the spindle of high-power engraving machine.

The diversity of spindle water chillers can meet the heat dissipation requirements of spindle equipment in various industries. Spindle carving machine water chillers with different cooling capacity are configured according to spindle power and water cooling parameters.